In this tutorial, learn to build a DIY Pecky Cypress table using epoxy resin. I show you various woodworking tips and techniques to make this build easier..

Even if you don’t need a pecky cypress table, the DIY tips covered in this build can be used on other woodworking projects.

Here are some jump links to the main sections of this post to hep you find the information you need quickly.

Video Tutorial

Table Design

Pecky Cypress Wood

Tools Needed

Step-by-Step Instructions

Video Tutorial

There are many things which are difficult to explain with words and images, so be sure to checkout the video tutorial below.

Pecky Cypress Table Design

During Christmas, the adults in our family pick names to exchange gifts.

I knew my mother in law wanted a new dining table, so I made sure to pick her name to build her an epoxy resin dining table using pecky sinker cypress.

I searched for cypress table ideas for about a day.

The unique look of pecky cypress quickly grabbed my attention.

This wood is fairly common in my part of the country (South Louisiana) & I thought it would be a great choice of wood for this epoxy resin dining table.

The wood is not only beautiful and unique, but it also has a lot of historical/geographical significance.

Ultimately, my Mother-in-law would appreciate the historical value.

Pecky Sinker Cypress Wood

I called a friend of mine who knows the best places to purchase reclaimed wood in the New Orleans area and he referred me to Riverside Lumber.

I visited Riverside Lumber the following day and noticed they not only had sinker cypress, but they also had pecky cypress.

Charles at Riverside Lumber was very helpful during my visits.

I would highly recommend them if you live in the area and in need of exotic or any type of lumber.

“Pecky” refers to a fungus that causes hollow tubes to run vertically throughout the tree.

The fungus grows while the tree is alive and only germinates when the tree is around 125 years old.

Ultimately, the fungus dies when the tree dies.

Tools I Used

- Epoxy Resin

- Oil and Urethane TopCoat

- Wood Carving Chisel Set

- Shop Vacuum

- Dust Deputy

- Orbital Sander

- Belt Sander

- Table Saw

- Japanese Finish Saw

- Biscuit Joiner

- Pocket Hole Jig

- Electric Hand Planer

- Benchtop Planer

- Bar Clamps

- Drill/Driver Combo

- Brad Nailer

- Wood Glue

- Silver Foil Tape

- Premium Tack Cloths

- GoPro Hero

Preparing the Pecky Sinker Cypress Wood

First, I decided to purchase these 2 pecky cypress slabs to build the resin dining table.

However, I later realized I needed an additional slab after my wife informed me 2 slabs were not wide enough to make a suitable table. Off to get another I went.

I also brought the first 2 pieces back with me to get planed down b/c the slabs were about 2.5” too wide for my planer. I didn’t realize this when I purchased the first 2 slabs (smh).

The pieces didn’t need to be planed down to any exact depth, but I wanted the surface as flat as possible b/c they were very rough and uneven.

Here are the 3 pieces for the pecky sinker cypress dining table.

Clean Pecky Sinker Cypress Wood

The next step for this resin dining table project was to remove the soft/damaged wood from the pockets..

I accomplished this by scraping as much of the wood out as possible with my wood carving tools.

Needless to say, this was quite a time-consuming process.

Many of the soft pockets caused by the fungus were much deeper and longer than I anticipated.

First, I scraped each pocket on both sides of each board and used my shop vac to remove the debris.

It may have been easier to use an air compressor and blow-out each pocket after scraping.

Next, I used my belt sander and orbital sander to get both sides of each pecky cypress board as smooth as possible.

I started with 150 grit sand paper on the belt sander and finished with 220 grit sand paper on the orbital sander.

Flat Surface and Straight Sides

After the pecky cypress boards were sanded and cleaned, it was time to square the sides of the boards in preparation for them to be joined together.

I need to upgrade my table saw soon with a larger table saw to make ripping long pieces of material easier.

I don’t have a jointer, so I used my table saw to rip an equal amount off of each board to make the table 36” wide (each board would be 12” long).

This worked out really well b/c 2 boards were 14” wide and 1 board was 15” wide.

First, I ripped 2” off 1 side of the first board, 1” on each side of the second board & 3” on one side of the last board.

Next, I saved the 3” board I ripped off of the last board to use on the table legs (more on this later).

I didn’t care if the outer edges of the table were perfectly straight b/c it is a reclaimed resin dining table.

Biscuit Joiner

The 3 pecky cypress slabs lined-up nicely, but I was concerned about which joinery method would be best to use on the pecky sinker cypress table.

Some of the ‘pecky pockets’ in the wood tunneled the length of the board and close to the edge.

I figured the strength of the table would be at risk if I used pocket holes to join the pieces near one of these tunnels.

In turn, I decided to use biscuits to join the 3 slabs b/c I can place the biscuits in solid parts of each board & the width of the #20 biscuits provided extra stability.

Most importantly, I had an excuse to go buy a new tool b/c I did not own a biscuit joiner.

Biscuit Spacing and Placement

First, it took me a while to figure out where to put the biscuits and how many to use.

Ultimately, I decided to use 6 biscuits per join (12 total).

There were a few biscuits that were visible on the underside of the table, but that was the best I could do.

Then, I clamped the pieces and let the glue dry overnight.

Also, I played with my new tool for about 2 hours.

Repair Creases between Pecky Cypress Boards

There were very minor creases between the pecky sinker cypress boards where I joined them together.

So, I lightly sanded the surface of the pecky sinker cypress table one more time.

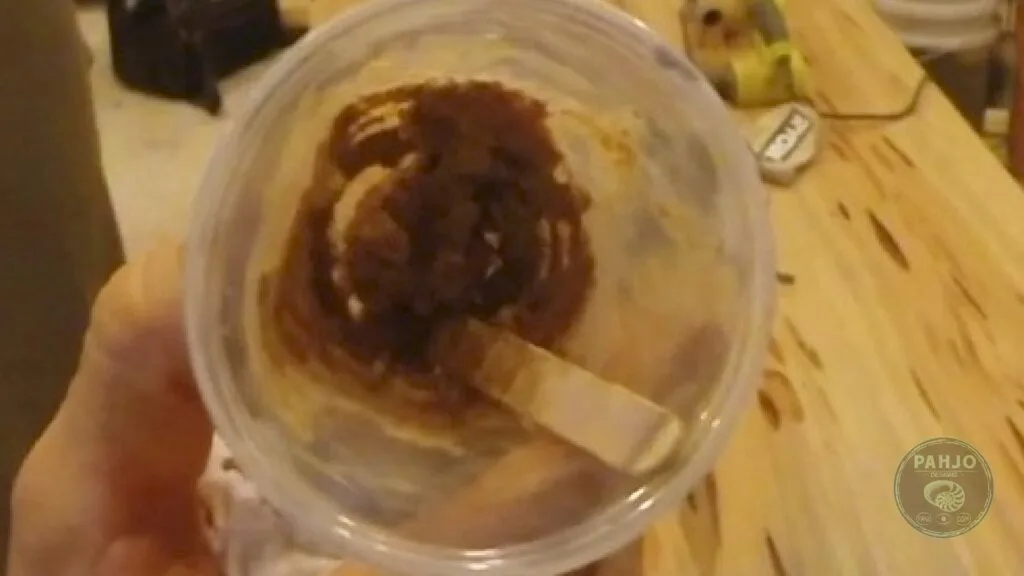

First, I mixed the sawdust in the bag with glue in a clear plastic cup to a putty-like consistency.

Next, I liberally spread the mixture over the creases and gently wiped off the excess with a popsicle stick because it was the closest thing within arm’s reach.

Remove Excess Glue

First, I lightly sanded the resin dining table surface of the pecky cypress table one more time to remove the excess glue/dust mixture and the creases disappeared.

Next, squared off the each end of the table with my circular saw to make it an even 76” long.

I used a damp towel to wipe the surface in order to raise the grain of the wood a small amount and lightly sanded again with 220 grit sandpaper.

Then, I vacuumed the pecky sinker cypress table surface again and used a tack cloth to make sure I get all the loose debris.

Ultimately, I used 2 tack cloths to wipe down this table while making sure to use a clean side of the cloth for each wipe.

Seal an Epoxy Resin Dining Table

Now to the tedious part. I flipped the pecky sinker cypress table top over and began taping the indentations and pockets with HVAC foil tape.

The idea was to pool the epoxy resin at the bottom to fill the cavities and prevent the epoxy resin from dripping through when poured on the top.

Use HVAC Table to Seal Epoxy Resin Table Bottom

I chose this tape for 3 reasons:

1.) I had an extra roll laying around my shop.

2.) It sticks really well to any surface & it is really strong.

3.) I didn’t know any better.

Instead of tape, a plastic sheet secured tightly to the bottom of this table should work as I’ve read epoxy doesn’t adhere to plastic.

However, I didn’t feel like running around the house or the big box stores searching for plastic and figuring out a way to secure it to the bottom to prevent sagging.

This process took me roughly 2 hours, which isn’t too long.

I made sure each pocket in the wood was covered completely even if the cavity seemed contained.

As I mentioned previously, many of the pockets formed channels in the middle of the wood that ran from one side to the other.

Also, I used a flexible plastic spreader to flatten the tape on the wood.

Choosing Table Top Epoxy

I had no idea how much resin/hardener I was going to need for this project before I started.

So, I bought 4 kits (totaling 4 gallons), but I only needed 3.

Keep in mind, this wood had a LOT of cavities/pockets – more than the typical Pecky Sinker Cypress slab.

I wrote a detailed article on how to choose the best epoxy for DIY projects so be sure to check it out.

Epoxy Resin Tip

The best advice I can give regarding using resin/hardener is follow the manufacturer’s instructions.

As you know, most men tend to glance over instructions and sort of figure it out as you go (I definitely fall into this category).

Keep in mind, you WILL have problems if you do don’t follow the instructions with any resin/hardener.

Mix Epoxy Resin

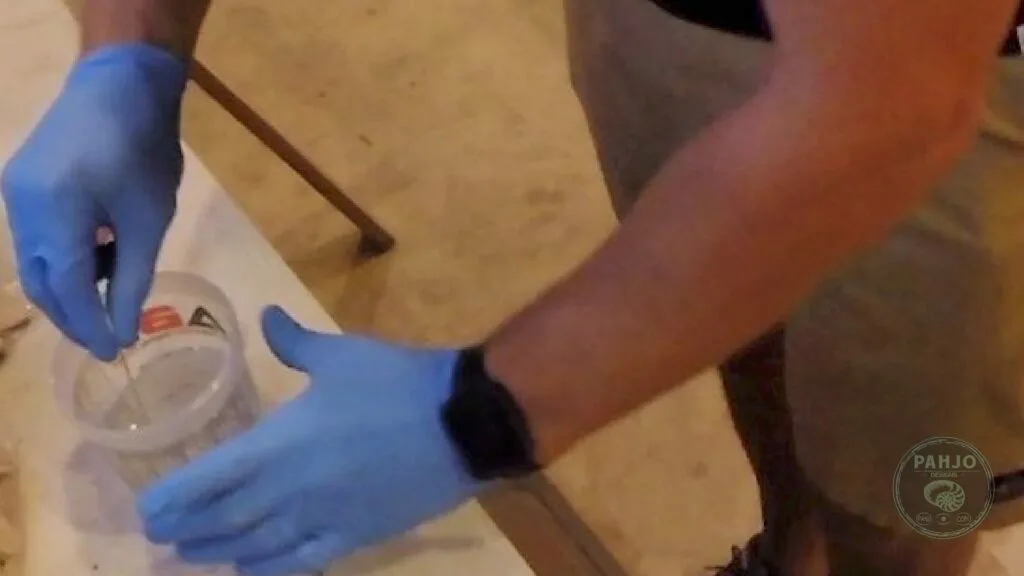

I started by mixing 1:1 ratio of resin/hardener that totaled 8 ounces.

Also, I knew this was a very small amount, but I wanted to make sure I got the hang of it before jumping to 10oz, 12oz or even 20oz mixtures.

This step is VERY important as most underestimate the amount of mixing this stuff needs.

Ultimately, I mixed (no whipping as this will create bubbles, which creates more work later) until the material was clear.

Apply Epoxy Seal Coat

This coat seals the entire surface of the table top and prevents any potential air pockets in the wood.

The mixture is poured onto the surface and then worked into the surface with a rubber squeegee.

There should not be any material build-up with this coat.

If the seal coat goes on too thick, air bubbles can get trapped in the cured epoxy.

Epoxy Fill Coat

This coat will fill the cavities/pockets in order to achieve a level surface.

Sand Epoxy Before Flood Coat

Epoxy needs a rough surface to adhere to.

So, I sanded the epoxy fill coat before proceeding to the flood coat.

Then, I cleaned the surface with a tack cloth.

Epoxy Flood Coat

This is the final coat and should be poured in the middle of the table and settle outwards (towards the ends).

Also, this coat self-levels (no squeegee wiping) up to 1/8” thick.

If you desire more than 1/8” thick, multiple coats need to be applied at least 4 hours apart.

Additionally, a squeegee or foam brush may be used to ‘guide’ the material around the surface, but no wiping.

Remove Tape

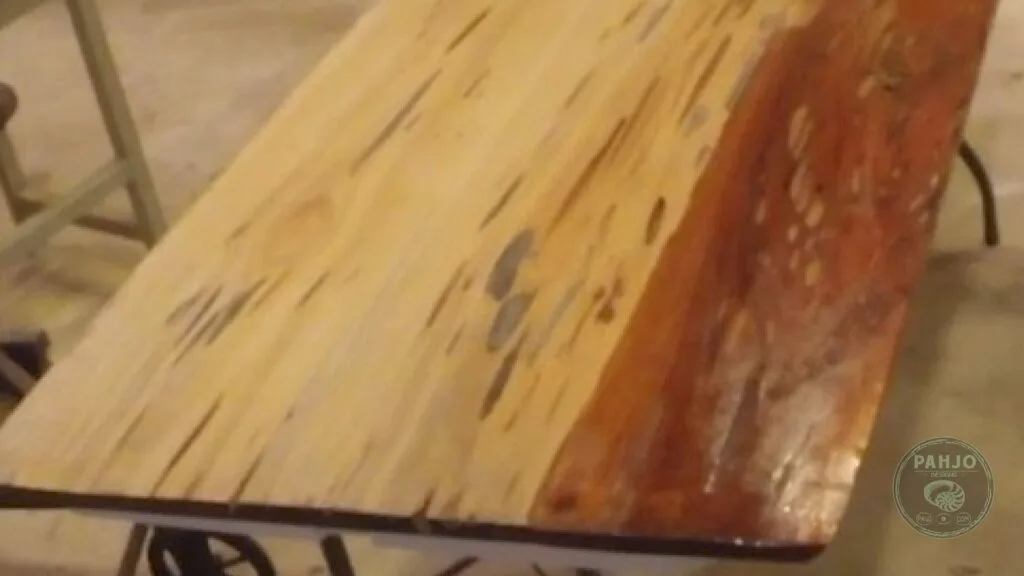

After allowing the pecky sinker cypress table to dry for 48 hours, I removed the tape from the underside of the pecky sinker cypress table, sand, and stain.

I used the belt sander to smooth the underside of the pecky sinker cypress table and used a brush to wipe off the dust.

Finishing Underside of Epoxy Resin Dining Table

I used Oil & Urethane sealer/topcoat to seal the bottom of the pecky sinker cypress table.

On the first coat, I made sure to get inside the pockets in the wood as they had a few on the underside of the table that did not protrude through the top.

Pecky Cypress Table Bottom

On to the table supports. I actually found a few table support designs that caught my eye online.

However, the plans called for holes to be drilled in the table top which I did not want to do.

My mother-in-law likes farmhouse & country style furniture, so that is the style I hoped to make.

Milling Resin Dining Table Support Wood

Most wood from the big box stores needs to be lightly sanded in order for the stain to properly penetrate the surface.

First, I ran each side through my planer as the wood was sort of in rough shape anyway.

This helped form a 4 straight edges on the wood instead of random rounded edges.

I wasn’t concerned about getting the wood perfectly flat/straight b/c the character of the Farmhouse table would hide many imperfections.

Half Lap Joints

I notched each leg for a cross-support brace on both support legs.

The ‘H’ design looked a bit plain and boring.

So, I measured to cut 4-45degree support arms for each support bracket.

8 support arms total.

I glued each piece in place and used my nail gun to secure them in place.

Next, I pre-drilled 4 pilot holes in each brace and used screws to secure the 45 degree braces in place.

I filled all holes with wood filler.

Once the wood filler dried, I sanded down the excess with both my orbital sander and belt sander.

Distress Wood

First, I scraped the wood with the grain using a flat head screwdriver.

Next, I dented the wood using a hammer, a hammer with a screw, and a hammer with a roofing tail.

Also, I used a very small drill bit to put holes in the wood.

After I gave the pecky cypress wood a fairly good beating, I clamped each support brace together to find any uneven spots.

Ultimately, this would cause me heartache later on when its time for the table top be put on.

I didn’t have noticeable uneven spots.

Next, I lightly sanded both support braces again with 220 grit sandpaper before attaching the foot pads.

Cross Support

I decided to use an upright 2×4 to tie the 2 support braces together.

I used my Kreg Jig to drill 2 pocket holes per side of the 2×4.

Next, I attached the 2×4 to the bottom of each support brace & filled the pocket holes with paint grade pocket plugs and glue.

Once the glue dried, I used my Japanese finish saw to remove the protruding plugs and sanded down to a smooth finish.

Apply Wiping Stain

First, I put a lot of thought into what color stain to use on the pecky sinker cypress table braces.

My wife is really good at picking out colors and she recommended I use an ebony or antique black.

The Pro Series wiping stain by Minwax was my stain of choice.

Essentially, I needed a stain that would be ‘thicker’ in order to prevent dripping.

In addition, it provided me with more control over the staining process.

I used staining cloth & a chip brush to reach the crevices.

Next, I applied the stain to approximately half of 1 support brace and wiped it down.

Also, this stuff goes on really well and it only needed 1 coat.

Farmhouse Dining Table Bottom

I used the wood I ripped from the original pieces of pecky cypress for the table braces.

Earlier in the project, I wiped these scraps with a paint brush from some excess epoxy.

They are about the size of a standard 1×3.

I used glue and my brad nailer to secure the piece.

Level Dining Table

Time to put the pecky cypress table on the support braces to see how it fit.

There were a few wobbly spots that were easily fixed with wooden shims.

I marked the shims with a black line at the cutoff point.

Then, I placed an ‘X’ of the side that needed to be discarded.

Next, I used my Japanese finish saw to gently saw the shims at the line I marked.

I secured the shims with glue and brad nails.

Removable Epoxy Resin Dining Table

The pecky cypress table needed to be removable, but I could not install threaded inserts.

So, I had to get creative.

I chose to make an outline of the upper 4×4 out of 1x2s and glue them in place.

Next, I placed the table on top of the braces and measured all 4 sides to ensure there was equal distance between the front/back and left/right.

Then, I traced the outline of the braces on the underside of the table once they were positioned correctly.

Lastly, I cut the 1x2s to size, glued them in position, and stained them to blend in with the support braces.

Epoxy Resin Dining Table Delivery

The finished pecky sinker cypress resin dining table looked great!

I delivered the table to my mother-in-law and she was very happy.

This epoxy resin dining table is definitely unique with a touch of local history as well.

Conclusion

I hope you learned how to build an epoxy resin dining table with pecky sinker cypress wood.

Related Posts:

Bond Corp

Tuesday 12th of January 2021

Very informative blog! All the information provided by you is really helpful for all. I agreed that tack cloth is the best cleaning tool than any other, it is really helpful for removing tiny dust particles over any surfaces. A good tack cloth makes your work easier. Thank you for sharing this article. Keep posting!

Michael Gill

Friday 26th of July 2019

Hi Jeremy! I am currently finishing a Pecky Sinker Cypress fireplace mantle for a friend from work. By the way I live on the Bogue Chitto River in Bush, Louisiana; so I when I came across your website I just had to check it out. I love how your table turned out! I'm sure Mom in law loves it. Sealed the pecky holes with shellac and I will mix aqua blue dye powder with the resin then mix in the hardener and pour just the holes level then epoxy the top with clear and let it flow over the edges so the thickness will be somewhat the same for the edges as it is for the top. I have and do gather and mill my own sinker logs from the Bogue Chitto river here in the Bush, La area. It's just my opinion but lumber milled from the sinker logs found in this river are the most beautiful of all sinker logs anywhere in the world! They absorb minerals from the silt on the river bottom that form blue green and red hues in the wood grain.... Amazing!!! I will send you some pics if I can get your email. I'll post mine here in a second. Anyway great looking table, keep up the great instructional posts your a natural teacher Jeremy. Go Tigers!

Ebru

Wednesday 12th of June 2019

Brilliant, I loved how detailed your explanations are. You have done a marvelous job. Now, I want to make my own but I would like to fill the wholes with brilliant, strong colors. If only I had a shop like yours... Thank you!

Rebecca

Saturday 17th of November 2018

Can you make me one of those tables?

Ann

Friday 9th of November 2018

Hi Jeremy!! Awesome table! I have a question about the Arm R Seal satin topcoat. How would you have used it on the table top instead of the high gloss finish? Thank you!!!!