In this tutorial, I show you how to build a DIY epoxy resin dining table from start to finish.

Also, I use these woodworking and epoxy techniques to build and sell furniture and art pieces to customers all over the world.

Even if you don’t need to an epoxy dining table, the DIY tips and techniques covered in this build can be directly applied to other epoxy and woodworking projects.

Here are some jump links to the main sections of this post to help you find the information you need quickly.

Video Tutorial

Project Overview

Tools and Material

Step-by-Step Instructions

DIY Epoxy Resin Dining Table Video Tutorial

There are several things which are difficult to fully explain with words and images, so be sure to check out the video tutorial below.

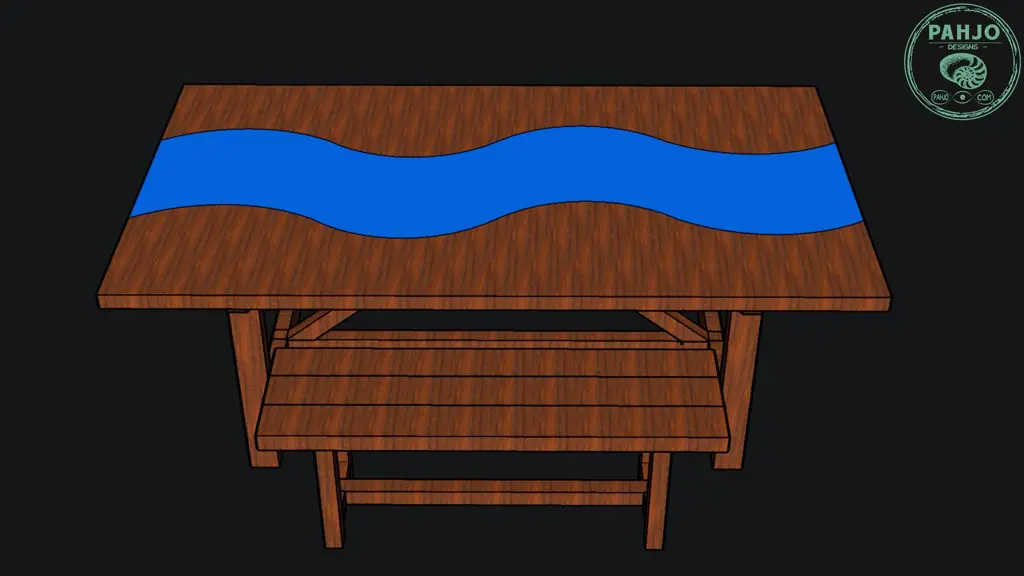

Project Overview

This epoxy table project was a BIG one.

I designed and built this custom black walnut slab dining table and matching dining table bench seat for a customer in Virginia.

The walnut dining table has 2 bookmatched live edge rustic walnut slabs with a blue epoxy river in the middle.

In addition to the table top, I built a farmhouse trestle bottom.

The table bottom and bench disassemble to make it easier to ship and move from room to room or house to house.

Lastly, each black walnut slab for the table top is 7 feet long, 4 feet wide, and 1.75 inches thick.

Step-by-Step Instructions

So, lets get started with a list of tools and material for this project.

DIY Dining Table Bench PlansDeep Pour Epoxy

Epoxy Drill Mixing Paddle

Pigment Powder for Epoxy

Epoxy Glow Powder

5 Gallon White Buckets

Odie’s Oil

Rubio Monocoat

Burn In Stick

Card Scraper

HEPA Vacuum

Rotex Sander

40 grit Sandpaper

60 grit Sandpaper

80 grit Sandpaper

120 grit Sandpaper

150 grit Sandpaper

180 grit Sandpaper

220 grit Sandpaper

320 grit Sandpaper

Polishing Pad

Scotch Brite Pad

Festool Domino

Router

Wood Slab Router Flattening Bit

Tuck Tape

Track Saw

Track

MFT3 Table

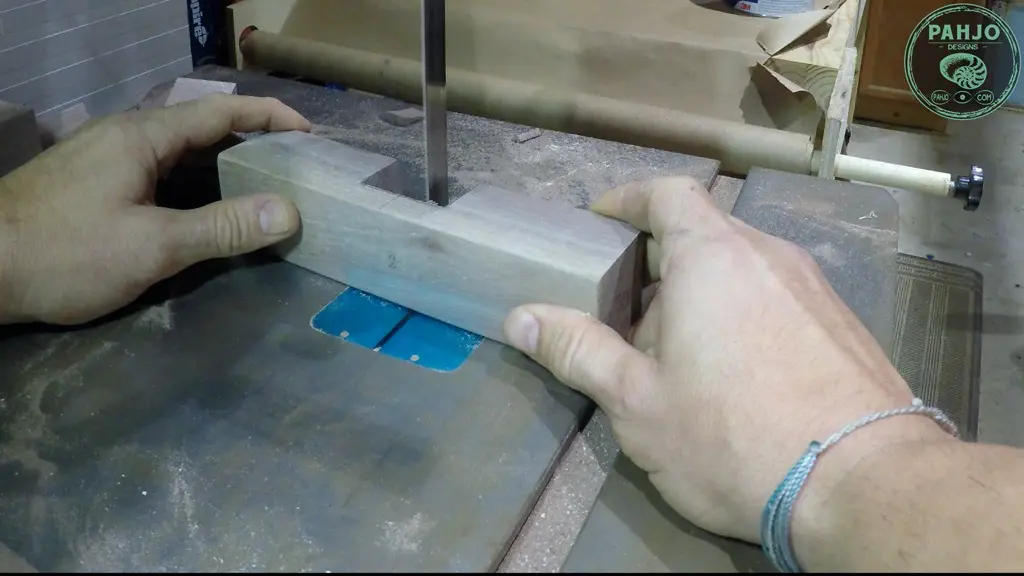

Bandsaw

Bandsaw Blade

Block Plane

Saw Horses

Chisels

Pocket Sander

Threaded Inserts

Furniture Glides

Drill Bit for Threaded Inserts

Drill

Large Speed Square

Parallel Clamps

F Clamps

Rough Sanding

In order to get a closer look at the wood grain, I sanded each live edge slab with 40 grit sandpaper using my rotex 125 sander in rotary mode on the highest speed setting.

I need to flatten the slab in a later step with my router, so this may seem like a wasted step.

However, I feel this step helps me visualize the final look of the table.

Plus, it doesn’t take long with my Festool Rotex Sander – maybe 15 minutes total for both pieces.

Remove Bark from Live Edge

The outer bark was removed from the live edge walnut slab by my hardwood dealer.

So, I only needed to clean the inner bark and loose debris.

First, I used my soft sanding pad on my rotex sander with 320 grit sandpaper to lightly sand the loose debris.

The soft sanding pad prevents aggressive sanding, which would change the shape of the live edge.

Flatten Wood Slab with Router

I used a router, flattening bit, and homemade router jig to flatten the underside of each walnut wood slab.

Also, I have 2 wood slab flattening jigs (small and large) and chose to use the smaller one for this task.

My smaller wood slab flattening jig consists of 2 90 degree aluminum rails with a 2 blocks of wood on each side.

The blocks of wood are about 1/4″ wider than the width of my router, which allows it to move freely across the jig.

The walnut wood slabs needed about 1/4″ taken off.

As a result, I made multiple light passes of roughly 1/16″ to 1/32″ per pass.

Once I flattened the underside of each slab, I flipped them over, positioned them, and traced the perimeter with a pencil to mark the location.

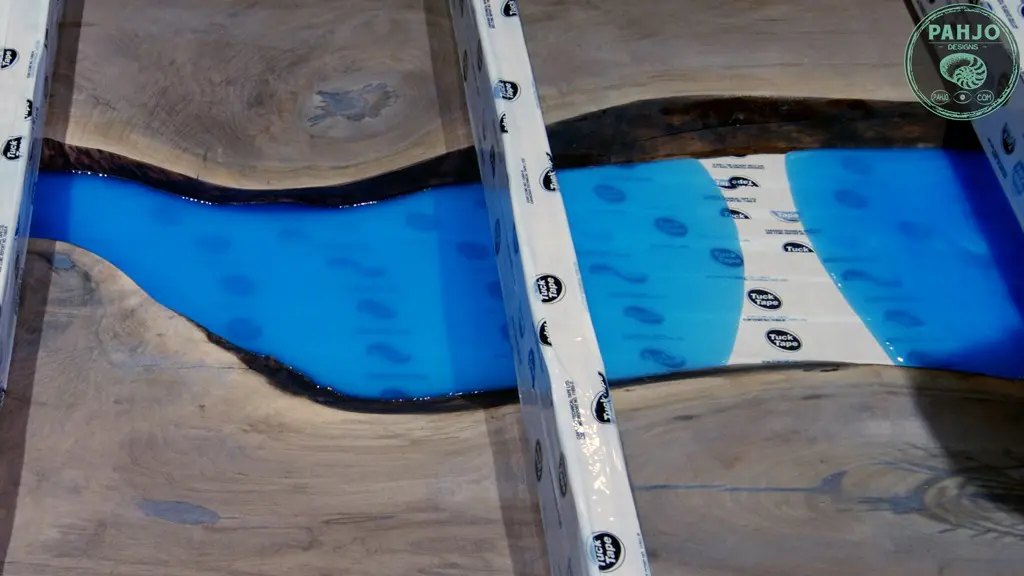

Next, I covered a 4×8 sheet of MDF with tuck tape (any sheathing tape works for epoxy molds).

The pencil marks remain visible under the Tuck Tape, so no worries there.

Filling Voids in Wood Slab with Epoxy

These rustic black walnut wood slabs had a few wood knots and voids. In turn, I filled the wood voids with epoxy.

I used deep pour epoxy because it penetrates the wood better than quick set epoxy.

Essentially, it soaks into the wood fibers because it is thinner.

In turn, it fills the voids and soaks into the wood.

While the epoxy cured, I sealed the wood slabs with silicone around the entire perimeter.

Measure and Mix Deep Pour Epoxy

I used Chill deep pour epoxy for this walnut slab epoxy dining table.

Also, I wrote an article about the best epoxy for wood projects, so be sure to check that out if you have any questions.

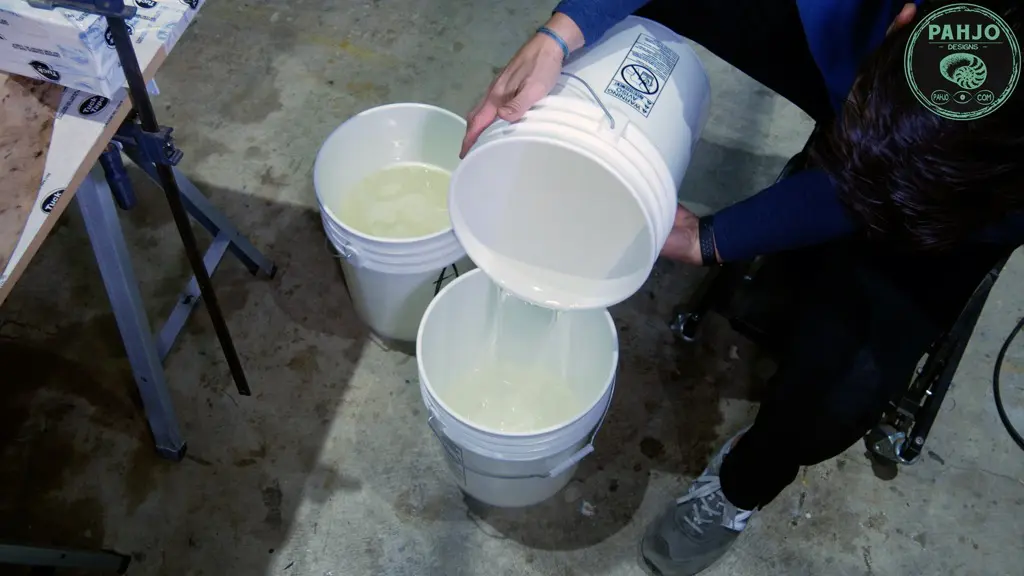

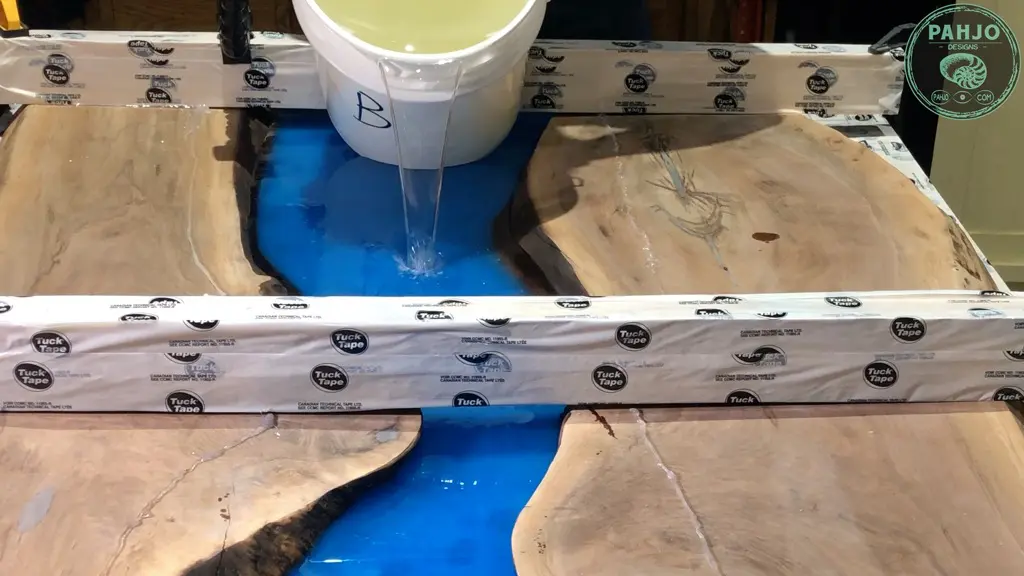

First, I used 3 buckets to measure and mix the epoxy resin.

Chill deep pour epoxy requires a 2:1 mixing ratio: 2 parts A to 1 part B.

I find it easier to accurately measure and mix epoxy with a bucket for part A, part B, and one bucket for mixing both parts.

In addition, I use the small containers to measure the epoxy before pouring it into the large bucket.

I could simply draw a dark line on the white bucket to mark the location, but a dark line isn’t accurate.

Next, I measured 2 parts A using the small containers and poured it into the large bucket.

Then, I measured 1 part B using the small container and poured it into the large bucket.

I poured part A and part B into the mixing bucket.

Once I poured part A and part B in the same bucket, I used a mixing paddle to mix the epoxy until it turned clear.

Add Pigment Powder and Glow Powder

After the epoxy turned clear, I added 2 shades of blue pigment powder.

I used Caribbean Blue and Blue Green pigment colors.

To get the proper color, I add a small amount of pigment powder, mix thoroughly, and repeat if needed.

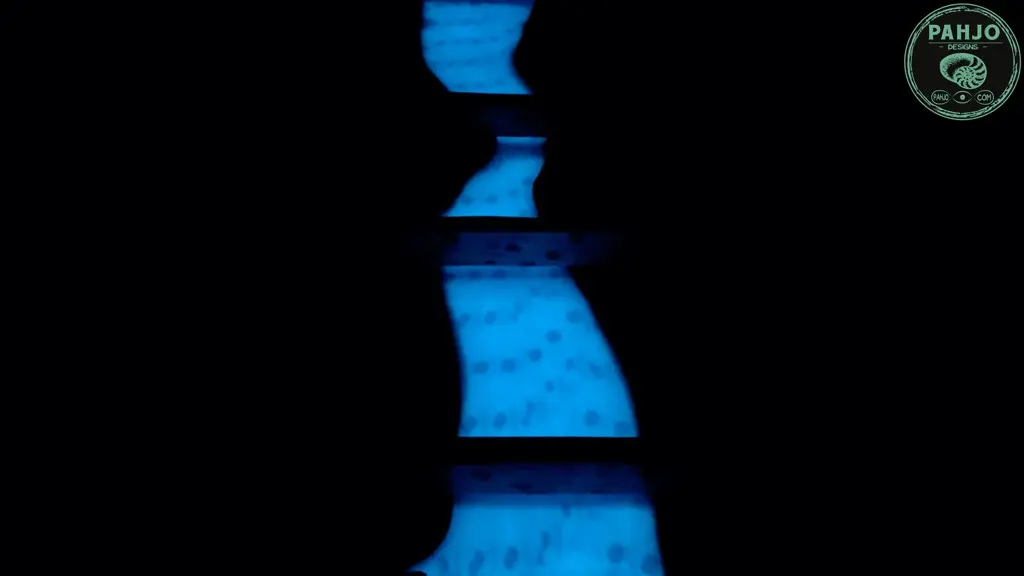

Next, I added blue glow powder and mixed thoroughly.

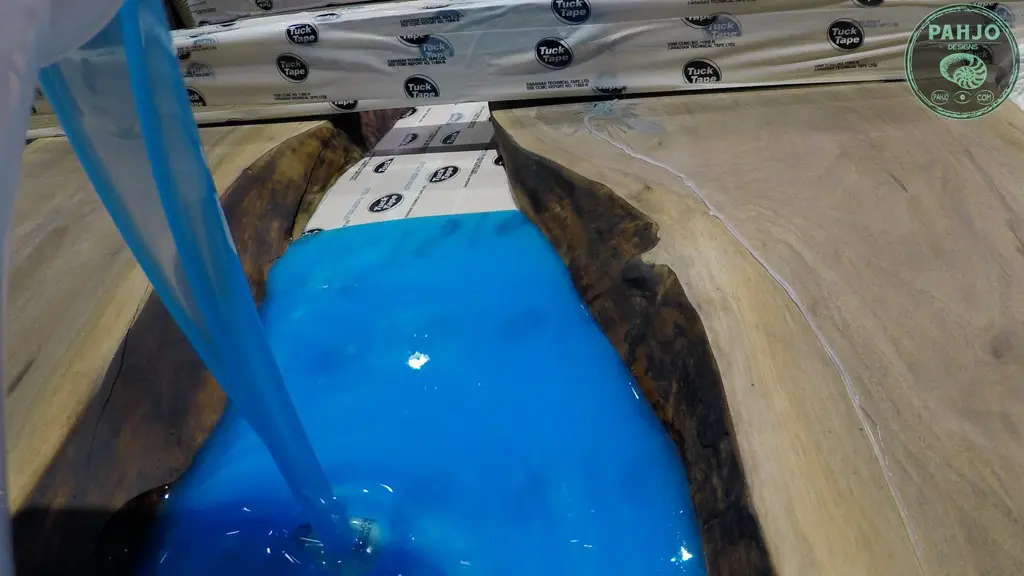

First Epoxy Pour

First, I created a resin calculator to accurately determine the amount needed for any project.

Complete the form below and I’ll email you a link to download it.

The first epoxy pour filled 1″ of the wood slab epoxy dining table.

My customer requested the live edge remain visible.

So, 1 colored pour followed by a clear pour satisfied this requirement.

Second Epoxy Pour

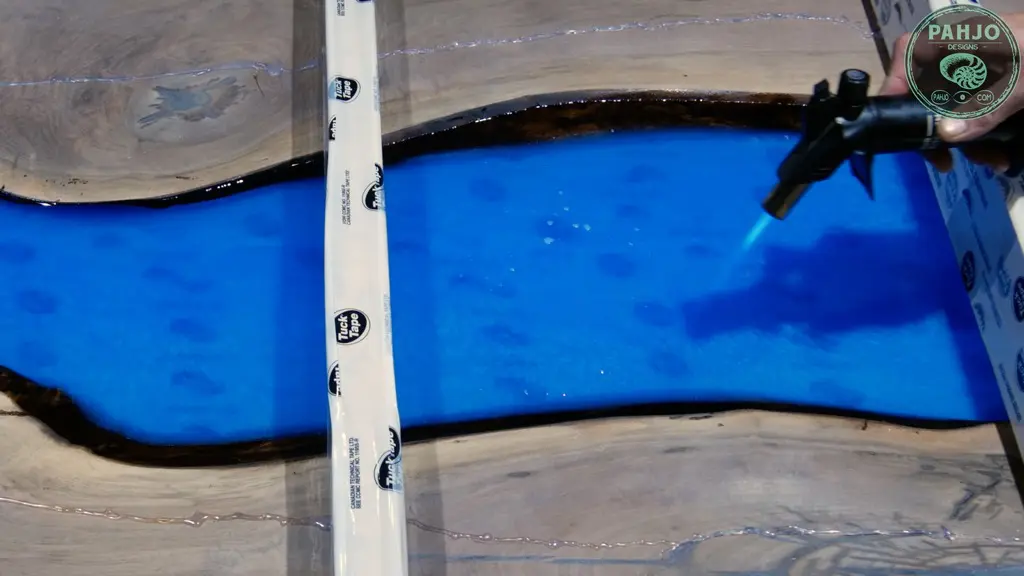

Once the bottom layer partially cured, I mixed and poured a clear epoxy top layer.

Also, I use the thumbprint test to determine when to pour a second layer of epoxy.

The epoxy is partially cured and ready for the second layer if I can leave a thumbprint without the epoxy sticking to my finger.

Next, I used a mini torch to remove the bubbles.

The glow powder in the walnut slab epoxy dining table charged from my shop lights and illuminated when I turned off the lights.

Remove Epoxy Table Top from Mould

Once the epoxy fully cured over a period of 7 days, I removed the epoxy mould.

Flatten Epoxy Wood Table with Router

First, I like to keep the top layer of epoxy just below the top edge of the table top.

Essentially, this allows me to only flatten a small amount of wood & epoxy to get a flat table top.

So, I used my large wood slab flattening jig with my router to flatten the epoxy dining table top as I normally do.

I used the same process to flatten epoxy wood tables with my router as I covered in the previous section.

However, I noticed epoxy leaked on the underside of the table when I flipped it over.

In turn, I had to use my router to remove the epoxy from the underside which I did not want to do.

Obviously, it is not fun to sand or plane down cured epoxy.

After the first pass, I used my dremel tool to sharpen my router bit.

I made 3 more light passes to remove the epoxy from the underside of the table.

Sand Epoxy Dining Table

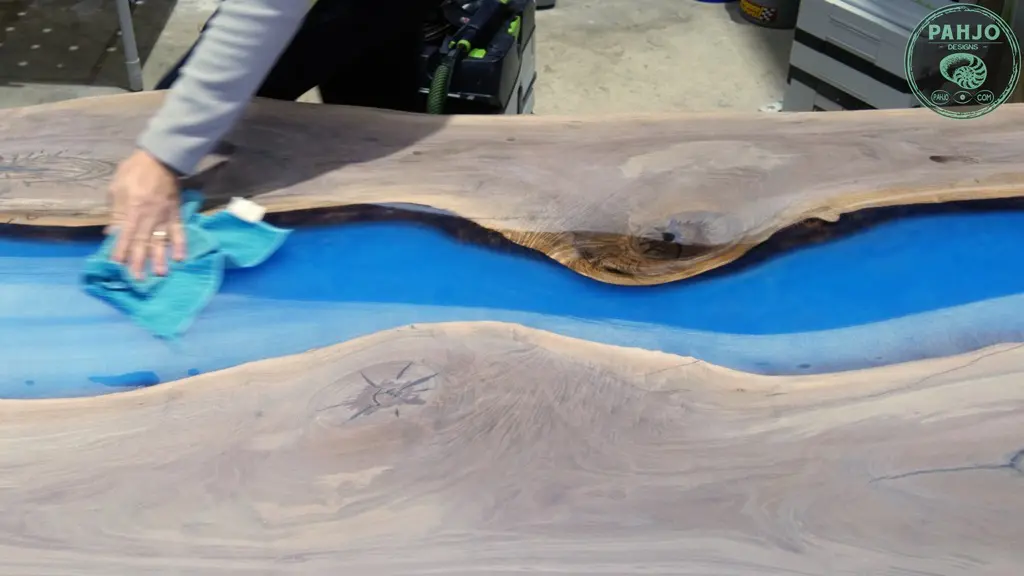

After I flattened the walnut slab epoxy dining table, I started sanding.

As a first step, I find it easier to sand the wood from 40 grit up to 220 grit while avoiding the epoxy.

After sanding the wood, I sand the epoxy with 120 grit and finish at 320 grit.

I developed a technique for sanding epoxy wood tables that prevents swirl marks and pigtails from forming.

First, I set my rotex sander on the highest speed setting in rotary mode.

Then, I make one light pass (forward and back) and use my air compressor to clean the resin from the sandpaper.

I repeat this process for the entire table.

I wiped the table with a damp towel to remove the dust.

While this process takes time, I don’t have to deal with burn marks, swirls, or pigtails in the epoxy.

Square Ends of Walnut Epoxy Dining Table

After I completely sanded the table, I used my track saw and track to square both ends of the table.

Fill Tiny Holes Burn In Stick

Once I wiped the table with a damp rag, I noticed there were tiny holes in a few knots from air bubbles.

Instead of mixing and pouring epoxy for these tiny holes, I used a burn-in stick (walnut color) to fill the holes.

Next, I used my card scraper to remove the excess.

Apply Odie’s Oil to Table Underside

I normally don’t finish the underside of my table tops.

However, I decided to use Odie’s Oil on the underside of this table.

Odie’s Oil is a great epoxy wood table finish that gets better with age.

First, I stirred the jar and placed a small amount on the walnut slab epoxy table.

Next, I used my rotex sander in rotary mode, polishing pad, and sheepskin pad to apply the finish.

Then, I allowed it to sit for 45 minutes and removed the excess with a terry towel.

Apply Rubio Monocoat to Epoxy Dining Table

I chose to apply Rubio Monocoat Oil Plus 2c on this epoxy wood table top.

First, I mixed rubio monocoat oil plus 2c and poured it on the wood slab dining table.

Next, I used a plastic spreader to spread the material from the middle of the table out towards the sides and edges.

Then, I used a towel to wipe the excess.

I used my rotex sander in rotary mode with a soft pad to buff off the remaining material.

2nd Coat – Rubio Monocoat Finish

Surprisingly, this table required a second coat of rubio monocoat.

I’ve used rubio on many tables in the past, but this is the first time I needed to apply a second coat.

So, I used a red scotch brite pad (800 grit equivalent) to scuff the surface very lightly.

Then, I repeated the process on the first coat.

I’m glad I applied a second coat because the table looked the way I envisioned afterwards.

Finally, I branded the underside of the walnut epoxy dining table as I do on all my custom furniture.

Walnut Dining Table Bench

In addition to the table top, my client requested I design and built a dining table bench to match the walnut epoxy dining table.

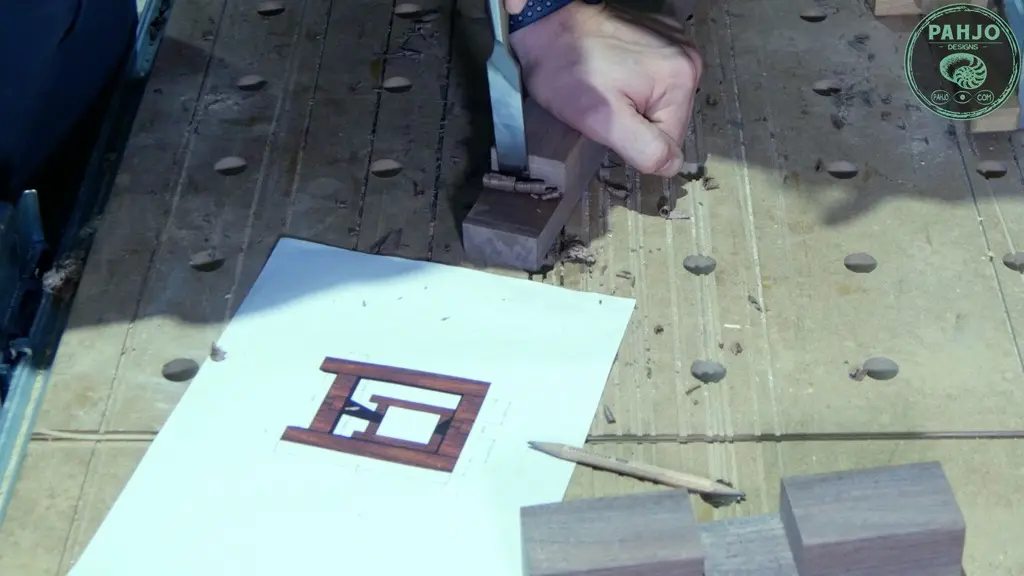

I designed the bench in sketchup using simple half lap joints and dominos to join the bench seat.

First, I used my track saw to get straight sides on the black walnut wood.

Next, I used my MFT3 table and squared off each end.

Then, I cut the half lap joints for the dining table bench seat bottom on my bandsaw.

I cleaned up the joints with my chisels, applied glue, and clamped the bench bottom together.

Dining Table Bench Seat

For the walnut epoxy dining table bench seat, I used my festool domino to join the bench seat.

First, I marked the locations of the dominos with my large speed square and labeled each mark.

Next, I cut the mortises at the marked locations, inserted the dominos, applied glue, and clamped them together.

I sanded the bench seat with 80, 100, 120, 150, 180, 220, and 320 grit.

Once I finished sanding with 320 grit, I wiped the dining table bench seat with a damp rag to raise the grain and sanded again with 320 grit.

In addition, I used this same process to sand the dining table bench bottom as well as the table bottom.

Dining Table Bench Disassembly

Since I needed to ship this table across the country, I designed the dining table bench to easily disassemble.

Apply Finish to Dining Table Bench

My wife helped me apply Rubio Monocoat to the walnut epoxy dining table bench seat and the bottom.

She always helps me when I ask, but she gets very nervous to mess up. So, I enjoy playing jokes on her.

Trestle Dining Table Bottom

My customer requested a farmhouse trestle table bottom for the walnut epoxy dining table.

Like the dining table bench, I designed the table bottom that disassembles to make it easier to ship.

Essentially, the dining table bottom has 3 pieces: 2 ends and middle.

First, I used half lap joinery to connect the trestle table bottom pieces together.

Regarding the trestle table design, I plan to write a separate detailed article on how to build a trestle bottom.

To accurately cut the trestle table bottom cross supports, I used f-clamps to hold the supports in place to mark a cut line.

Next, I used my bandsaw and hand sander to cut the correct angle and sand it smooth.

Then, I used my festool domino to attach the trestle table cross supports to the table bottom.

I glued and clamped them together and allowed it to dry.

Lastly, I used Rubio Monocoat to finish the trestle dining table bottom.

How To Attach Table Top to Base

This method for attaching table bottom to table top uses threaded inserts along with wood blocks, which makes it easy for customers to attach and detach.

Additionally, it allows for wood movement.

Pack Dining Table for Shipping

I disassembled the dining table top, trestle bottom, and bench for shipping.

I wrote on article on how to pack and ship furniture, so be sure to visit that article to learn more.

Customer Delivery and Assembly

I spoke to my customer after I received a notification the custom walnut epoxy dining table was delivered.

By the time I called him, he finished the table assembly based on my instructions. He said it was super easy to assemble and took him 15 minutes.

Ultimately, my customer was very satisfied with the table.

Related Posts:

- How to Fill Wood Cracks with Epoxy

- How To Sand Live Edge Wood

- 3 Ways to Ship Furniture

- DIY Dining table Bench Seat

Frequently Asked Questions

The best epoxy for wood tables is Total Boat epoxy.

Custom built epoxy tables sell for $3,000 dollars on average.

A dining table bench should be at least 12 inches wide and 36 inches tall.

A trestle dining table is a piece of furniture which a table top is placed. It has 2 end supports linked togther by a cross support. The trestle table is often used as farmhouse style furniture.

Paul M

Monday 2nd of November 2020

What dimension of board did you use for your trestle table base? Trying to make something similar and am trying to decide using 2x4 or 2x6 as a starting point.

Jeremy

Wednesday 18th of November 2020

Hi Paul, I cut the walnut to 2" x 4". Keep in mind, this is the actual size.

BAUMGART GUY

Friday 17th of July 2020

Etant débutant dans la matière j'ai appris pleins de choses intéressantes. Merci.