In this tutorial, I teach you how to build base cabinets with drawers for a desk, craft table, or table.

Even if you don’t need to make desk cabinets, the DIY tips and techniques in this tutorial can be used on other woodworking projects.

Here are some jump links to the main sections of this post to help you quickly find the information you need.

Video Tutorial

Tools and Material

Step-By-Step Instructions

DIY Video Tutorial

There are several things which are difficult to fully explain with words and images.

So, checkout the video tutorial for this cabinet build below.

Tools and Material Needed

2 Plywood Sheets

Cabinet Drawer Slides

Drawer Slide Wood Screws

Jig Drawer Slide

Wood Glue

Glue Bot

Drill

Pocket Screws for Assembly

Brad Nailer

1.25″ Brad Finish Nails

Air Compressor

Retractable Air Compressor Hose

Pilot Hole Drill Bit

Bar Clamp for Cabinet Assembly

F-Clamp for Drawer Assembly

Paint Sticks

Craft (Popsicle) Sticks

Wood Filler

Festool RO125 Sander

220 Grit Sandpaper

Festool Dust Extractor

90 Degree Positioning Squares

Combination Square

Dewalt Router

1/2″ roundover bit

CA Glue with Activator

Magnetic Torpedo Level

Pocket Hole Jig

Pocket Hole Screws

Table Saw or Circular Saw

Chalk Paint Brush

Drawer Pulls

Introduction

This project is part 2 of my Epoxy Resin Ocean Glow Table I built for my wife as a Mother’s Day gift.

However, these DIY base cabinets can be used on any table or desk in need of a table base with storage.

Since the ocean glow table is my wife’s craft table, I needed to build a table base with drawers to store her cricut accessories.

So, I designed the DIY base cabinets from scratch and started building it shortly after I completed the ocean table.

Also, I show you how to make drawers, how to install drawer slides, and how to build a cabinet carcass.

DIY Base Cabinet with Drawers Plans

Be sure to download the base cabinet plans I created for this project.

Whether you plan to build your own cabinets for a new kitchen, shop cabinets, or drawer base cabinets, these plans guide you through the building process.

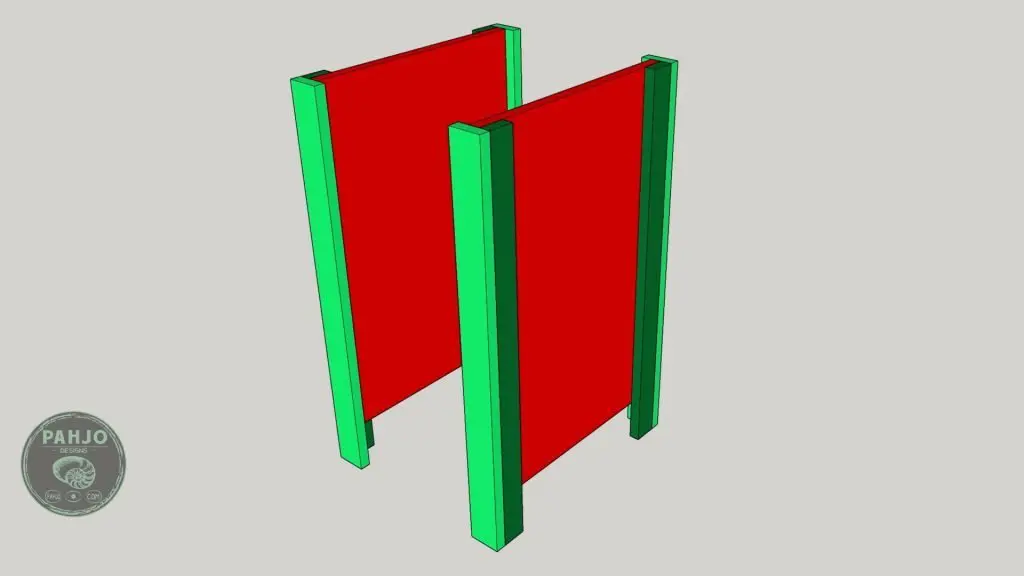

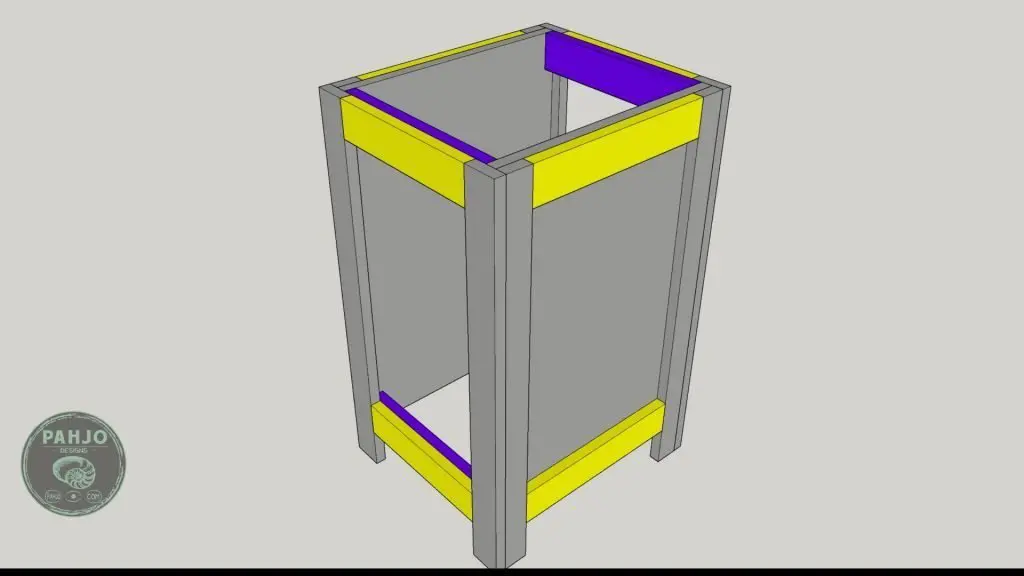

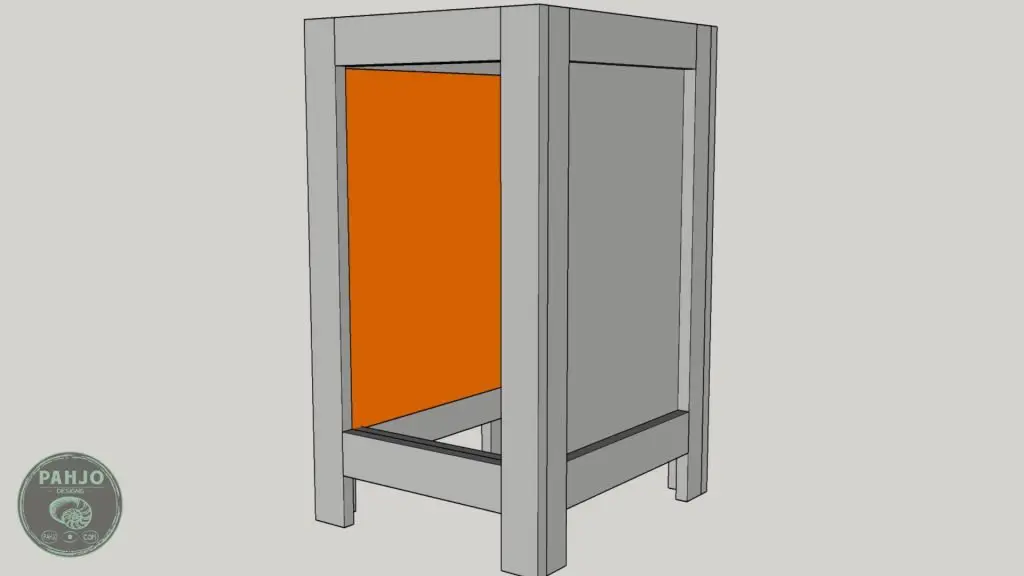

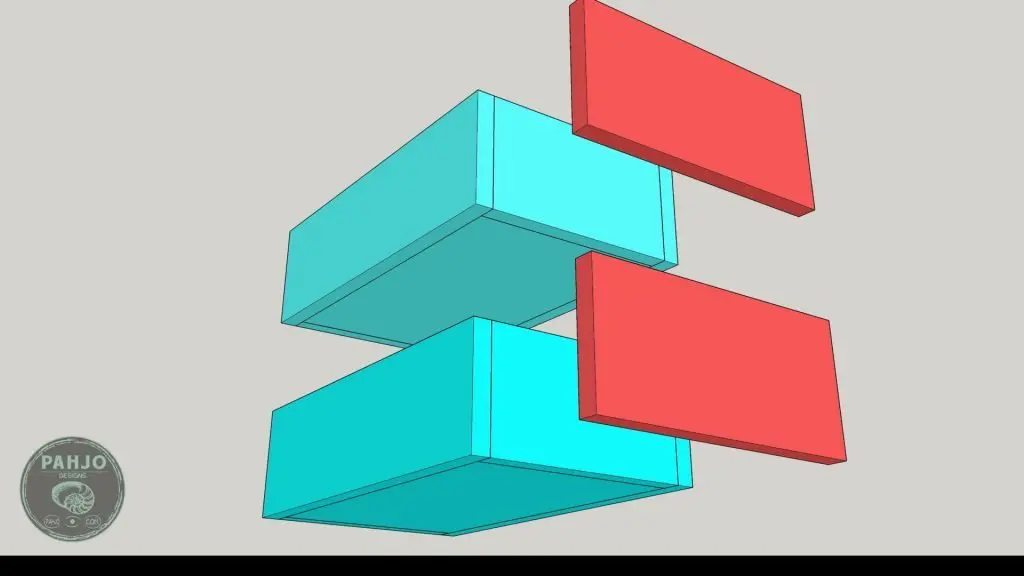

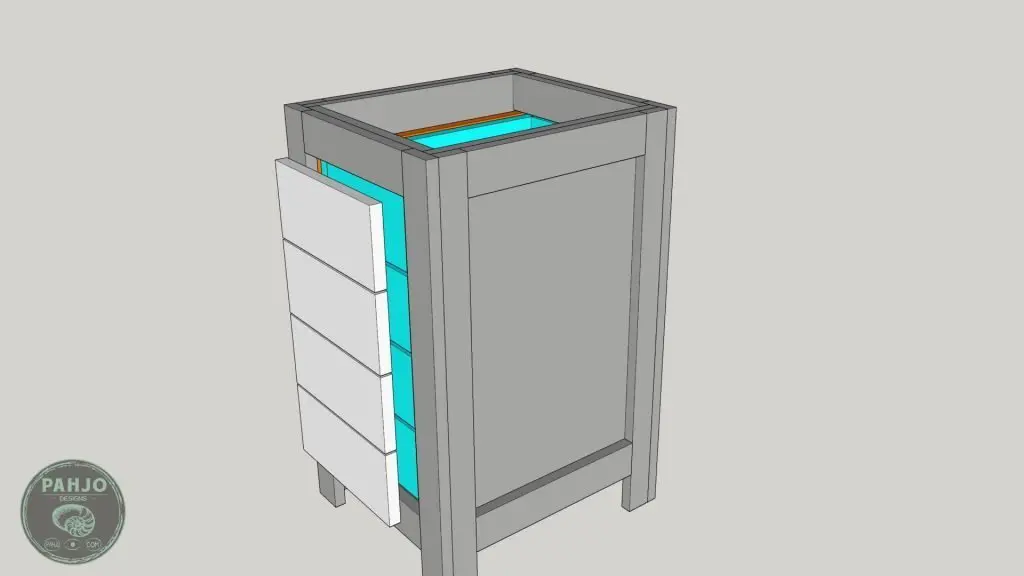

The image below provides a general overview of cabinet parts:

- Drawer Fronts (Pink)

- Drawer Boxes (Aqua)

- Side Panels (Red)

- Face Frame Cabinets (Green, Yellow)

- Cabinet Carcass (Dark Green, Purple, Orange)

Basic Carcass Construction

First, line up the corner pieces and put down a line of glue on one edge of the ‘Front Short’ piece.

Spread the glue with a glue spreader or your finger.

I chose to spread the glue on all these pieces at once to save time.

If you choose to do it this way, be sure to work quickly to avoid the glue drying prematurely.

Next, flip the ‘front short’ piece on a flat side facing the ‘front long’ piece.

The ‘front long’ piece should be upright on its side as shown below.

Using a speed square or L-Square, perform a quick 90 degree angle check.

After the pieces are aligned, secure them with 3 brad nails (2 sides and middle).

Keep in mind, the brad nails simply hold the 2 pieces together until screws are used.

Cabinet Side Pieces

Next, take 2 corners you just made and 1 ‘side outside’ as labeled in the cut list.

Then, lay the corners down on the flat surface and make sure the ‘front short’ piece is laying flat and the ‘front long’ piece is perpendicular.

Apply and spread glue on the ‘front short’ piece from the top and 25” down on each corner pair.

Afterwards, lay the ‘side outside’ piece on top of the glue and secure with brad nails.

Repeat the same process with the pilot hole, countersink bit, and pocket screws as before.

Cabinet Base Horizontal Supports

Get one side from the previous step and lay it perpendicular on flat surface.

Next, place glue on each one end of the ‘inside runner’ and place it on the side as shown in the picture below.

Then, use a speed square or L square to make sure the inside support pieces are perpendicular to the side.

A 90 degree corner square is a great way to keep the interior panels square.

Use 2 brad nails to secure the piece followed by 2 screws in the pilot hole.

Cabinet Carcass Inside Sides

As a next step, spread a liberal amount of glue on one side of the ‘inside side’.

This piece is supported from the bottom runner and top stretcher, so a clamp is not needed to secure it.

Next, use brad nails to secure the piece.

Then, drill a pilot hole in each corner (4), followed by a countersink bit and screws.

Cabinet Drawers & Drawer Faces

The easiest way to assemble drawers is to start with the bottom, front, and back piece.

Keep in mind, the drawers fit within the cabinet depth.

First, lay the bottom down on a flat surface.

Next, spread glue on the front bottom and back bottom.

Then, stand them in place (bench dog or something similar helps) and check for 90 degree angle.

Additionally, you may find it easier to hold the L square on the drawer bottom and push it against the front/back while driving 3 brad nails in the middle and both sides.

Like before, make pilot holes, countersink them, and drive in 3 screws.

Afterwards, turn the drawer on its side and spread glue along the bottom, front, and back piece.

Lay the drawer back down on the flat surface, push the side piece in place, check for square, secure with brad nails, and then screws.

Drawer Faces

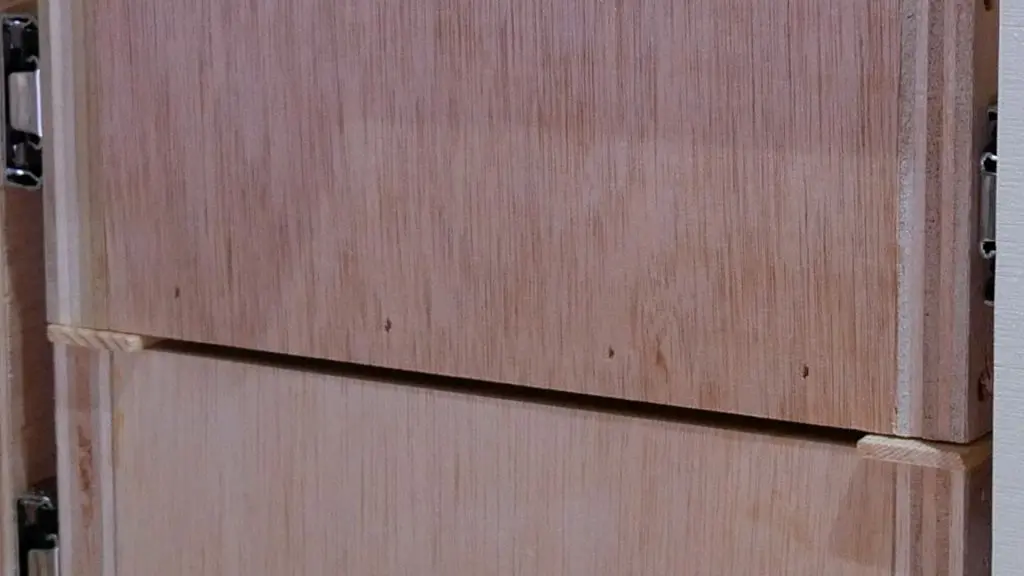

This DIY base cabinet with drawers has inset cabinet doors, which means the drawer face will be flush with the face frame or front of the cabinet.

I cut the drawers and ran them through my router with a ½” roundover bit.

Decorative Drawer Knobs

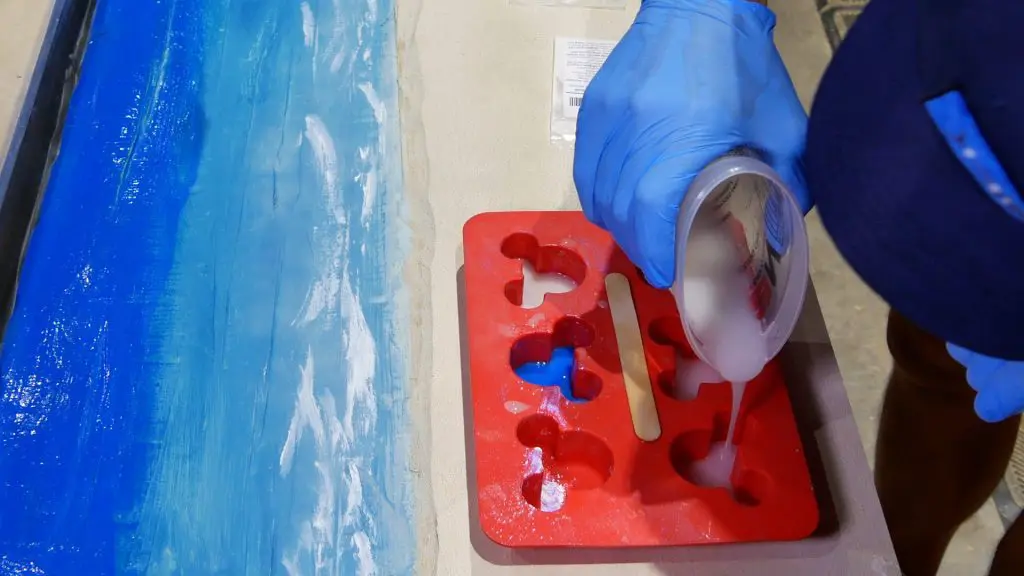

In order to match the Ocean Table, I used epoxy resin silicone molds of sea creatures and mickey mouse ears.

Also, I made most of these with excess epoxy resin after a resin pour.

Although these are not the easiest knobs to install, they certainly match the table well.

Fill Holes and Sand

First, I used wood putty to fill the holes and allowed it to dry per the instructions.

Next, I used my orbital sander with 220 grit sandpaper to sand it down.

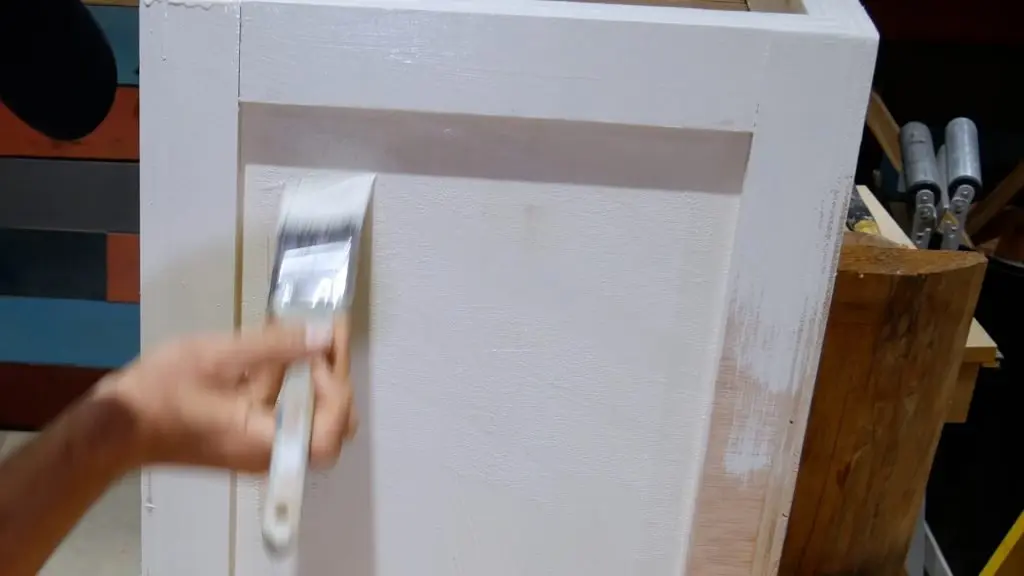

Paint Base Cabinets

First, I painted the entire cabinet carcass and drawer faces with chalk paint that I mixed myself from leftover Sherwin Williams satin paint (color SW7008).

Also, I have a ton of experience with painting and I really don’t like doing it, which is why chalk paint is the perfect solution for many of my projects.

What are the advantages of chalk paint?

- Chalk paint goes on evenly

- Dries quickly

- Leaves a flat finish

- Covers more surface area

Attach Drawer Knobs

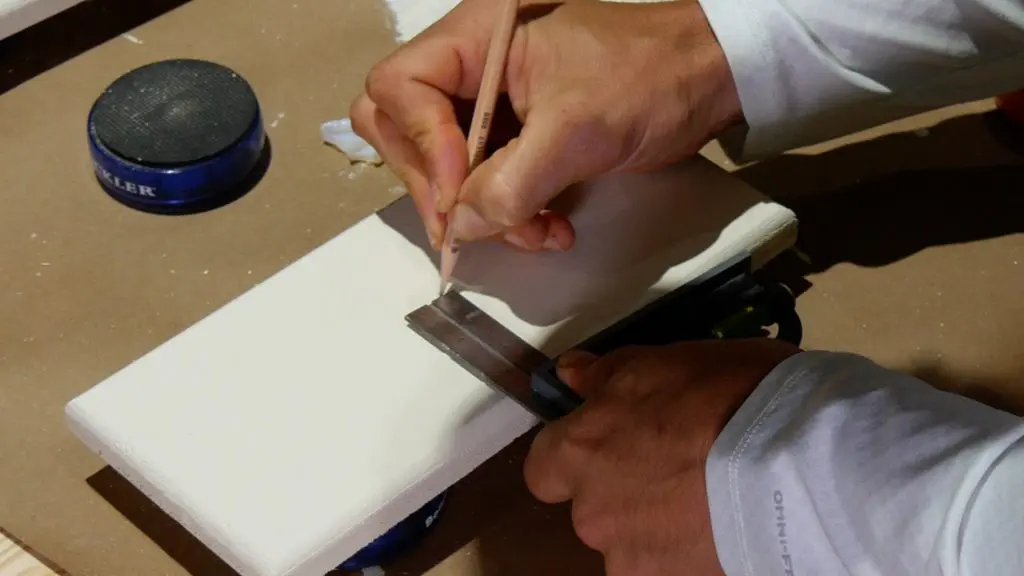

First, find the center of the drawer face.

Then, measure the width and divide by 2. The center of the drawer face is where these lines intersect.

Next, place a small amount of CA glue around the hole on the drawer face and spray activator on the back of the resin knob.

Finally, press the resin knob on the center of the drawer and hold for roughly 5 seconds.

Base Cabinet Inset Drawer Installation

First, make sure the bottom drawer has a support which is even with the bottom frame.

Next, I had to get creative with this step because I didn’t want to waste a piece of wood for the base cabinet support for the bottom drawer.

A leftover piece of sinker cypress from a previous project along with 2 paint sticks and 2 popsicle sticks was perfect for a base support.

Keep in mind, Each paint stick is ⅛” thick and a popsicle stick is 1/16” thick.

I turned the sinker cypress 45 degrees so that it would balance the drawer when placed on top of it.

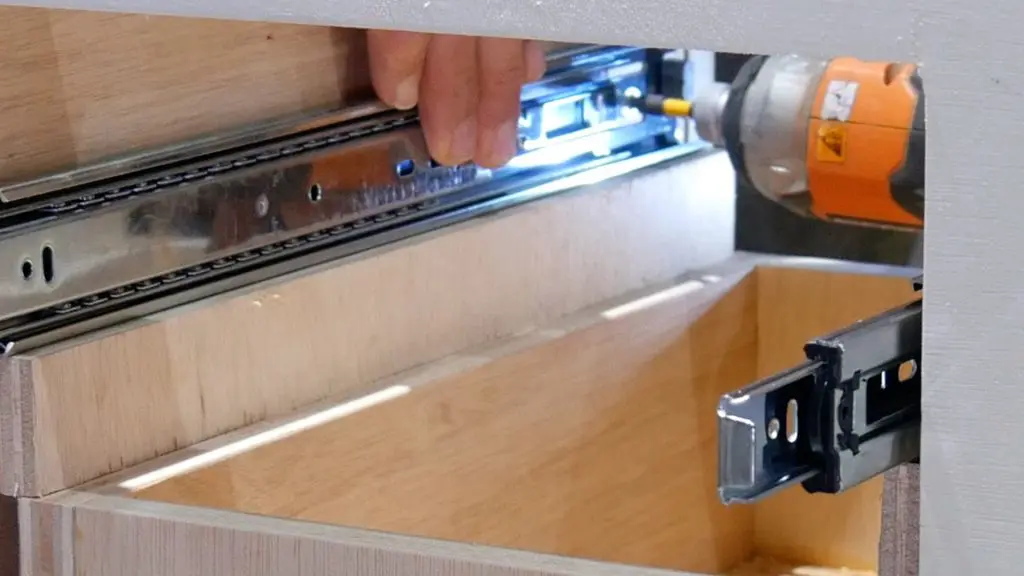

Next, I cut 2 pieces of scrap ¾” plywood the length of the cabinet frame (18”) and 1.5” wide for the drawer slide to rest on.

Then, place the drawer slide on top of the scrap piece of plywood and make sure it is aligned/flush with the back of the ¾” cabinet face frame.

Remember, this is an inset cabinet so ¾” of an inch is needed for the drawer face.

Also, it is a good idea to place the magnetic torpedo level on top of the drawer slide to make sure it is level.

Next, gently slide the drawer slide forward to reveal the holes in the back of the slide. While holding the slide in place from the rear, drive 3 cabinet screws in the holes provided.

Ultimately, it doesn’t matter what holes are used as long as they are spaced appropriately (rear, middle, front). Finally, remove each scrap piece of plywood.

Fasten Drawer Slide to Drawer

First, place 2 paint sticks on top of the bottom support to lift the drawer ⅛” from the bottom as depicted in the drawing at the beginning of this section.

Next, place the drawer on top and ensure the paint sticks are supporting the drawer evenly.

The drawer should fit snugly between each drawer slide.

Base Cabinet Drawer Face

First, drill 2 pilot holes and counter sink into the back of the drawer front.

Next, place 2 popsicle sticks on top for the 3 bottom drawers and on bottom of the top drawer.

Then, align the drawer face so that it is flush with the popsicle sticks minus about a tiny bit (1/32”).

Afterwards, drive 2 pocket screws to secure the drawer face from the rear.

Lastly, check to make sure the drawers fit and adjust if needed.

Easy Method to Attach Base Cabinets to Table Top

First, I used my kreg pocket hole jig and clamp to make 2 pocket holes per cabinet base – one on the left and one on the right.

Moreover, this prevents the table from moving or sliding.

Pocket holes are perfect for this application because I may want to remove it in the future.

Conclusion

In summary, I hope you learned how to build base cabinets with drawers.

Related Posts

- How Much Does it Cost to Paint Kitchen Cabinets

- DIY Built Ins

- Best Wood for DIY Cabinets

- How High to Hang Kitchen Cabinets

What Is a drawer base cabinet?

A drawer base cabinet is a type of kitchen or storage cabinet. It is designed primarily for storing items in drawers rather than shelves or doors. These cabinets typically have multiple drawers stacked vertically, providing convenient storage and organization for various items such as utensils, kitchen tools, and other small items.

What is the difference between face frame and frameless cabinet hinges?

Face frame cabinets have a front frame attached to the cabinet box, providing structural support. Hinges are typically mounted on the face frame, and doors often overlay it. In contrast, frameless cabinets lack a face frame, featuring doors and drawers directly attached to the box. Frameless hinges are usually mounted inside the cabinet, offering a concealed look. The choice between face frame and frameless hinges depends on design preferences and the desired aesthetic – face frame cabinets are more traditional, while frameless cabinets provide a sleek and modern appearance.

What are the parts of a base cabinet with drawers?

A base cabinet with drawers comprises the cabinet box, which forms the main structure and encloses the storage space. The cabinet typically features multiple drawers with varying sizes and depths. Drawer fronts, the visible faces when closed, come in various styles. Drawer glides or runners enable smooth sliding, and drawer pulls or handles serve both functional and decorative purposes. The cabinet may rest on legs or a base with an adjustable toe kick at the bottom front. The back panel provides additional stability to the structure. Understanding these components is crucial for choosing, installing, and organizing base cabinets with drawers effectively in a kitchen or storage area.