In this tutorial, I show you 5 useful tips for sanding epoxy resin to get a smooth and polished finish.

In fact, I use this sanding process on my epoxy wood tables, bar tops, and river tables for my clients all over the world.

Learn how to control epoxy resin sheen levels, the best way to sand large projects, and much more.

Here are some jump links to the main sections of this post to help you find the information you need quickly.

Video Tutorial

Tools for Sanding Epoxy Resin

Dry Sanding vs Wet Sanding

5 Tips for Sanding Epoxy Resin

Sanding Epoxy Resin Video Tutorial

There are several things which are difficult to fully explain with words and images, so be sure to check out the video tutorial below!

Best Tools for Sanding Epoxy Resin

Most of the time, tools do not matter – until they do.

Tools matter when sanding epoxy resin projects.

Not only do quality tools help you produce good results, but they also keep you safe.

Soft Sanding Pad

Protection Pad

Dust Mask

HEPA Vacuum

Sandpaper Abrasive Cleaning Stick

Spray Bottle

120 grit Sandpaper

150 grit Sandpaper

180 grit Sandpaper

220 grit Sandpaper

320 grit Sandpaper

400 grit Sandpaper

What is the Best Way to Sand Epoxy Resin?

Essentially, there are 2 ways to sand epoxy resin: Dry Sanding and Wet Sanding.

Wet sanding with water-resistant sandpaper is the best way to sand epoxy resin.

However, it depends on the type of project.

This tutorial focuses on dry sanding epoxy resin.

I’ll briefly review both methods.

Dry Sanding

Wood and resin projects require dry sanding.

The main reason for this is water may cause the wood to swell.

As a result, your project could have uneven surfaces.

With that said, dry sandpaper causes heat which may dissolve the resin or permanently dull the sheen to a matte finish. Furthermore, dry sanding produces a lot of dust.

Luckily, the tips I share with you in this resin sanding guide prevent these issues.

Wet Sanding Epoxy Resin

Wet sanding with waterproof sandpaper is the preferred method to sand epoxy resin.

It produces less heat, removes uneven surfaces, reduces the amount of dust, and keeps sandpaper clean.

However, wet sanding of epoxy resin is not all sunshine and rainbows.

Wet sanding with an electric sander can cause electric shock. Moreover, sanding large areas by hand requires a lot of time.

How To Sand Epoxy Resin Surface (5 Tips)

Whether you want to improve your resin sanding technique for better results or prevent costly mistakes, these 5 tips on how to sand a resin piece will help you.

1. Sanding Resin and Wood Separately

If possible, sand the wood and epoxy resin separately.

Obviously, this only applies to wood and resin projects such as epoxy river tables.

This prevents fine resin dust from embedding into the wood fibers (referred to as ‘burn-in’).

An epoxy resin surface and wood each require a different sanding technique and sandpaper grit sequence.

So, the best method is to treat them as 2 different surfaces.

Keep in mind, it’s ok if you can’t sand them separately or overlap an inch or two.

Be sure to follow the next tip if you need to sand wood and resin together at the same time.

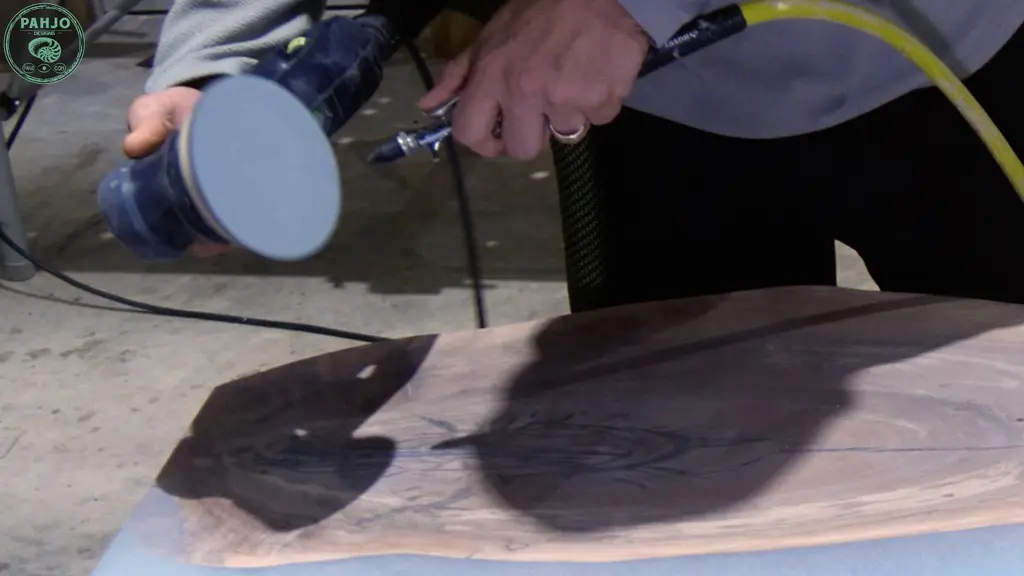

2. Keep Resin Sandpaper Clean

Sanding requires friction and friction produces heat.

Consequently, this causes fine resin dust and sanding residues to build up on the sandpaper.

The dust and residues rest between the sandpaper and the epoxy surface.

If not removed, this build up could cause sanding swirl marks, pigtails, burn-in, and deep scratches on the resin surface.

To keep the sandpaper clean, use an air compressor or sandpaper cleaning block and follow these steps:

- First, make 1 or 2 passes over the resin.

- Next, remove the sander from the surface.

- Then, use an air compressor to remove the resin dust from the sandpaper.

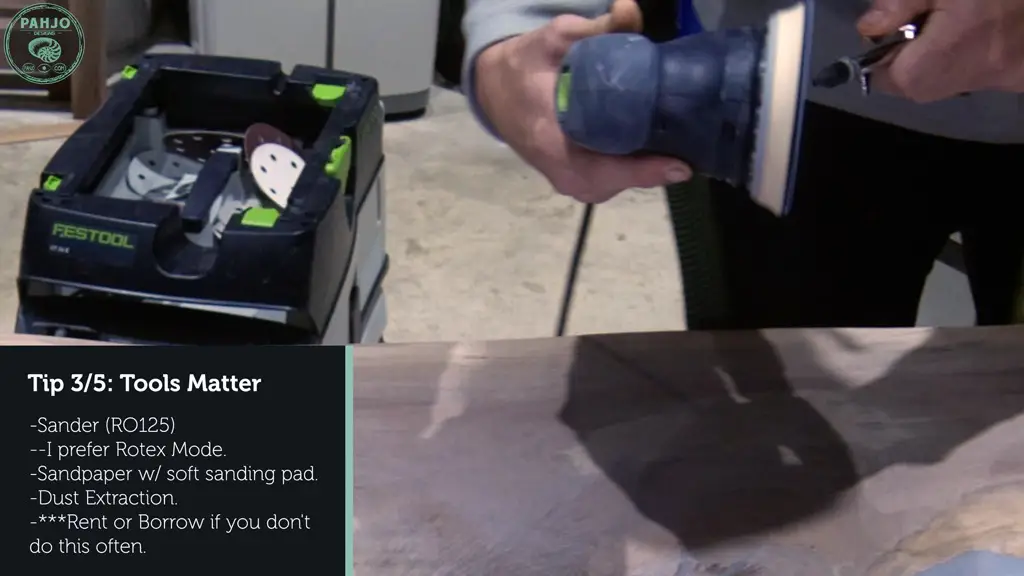

3. Use Proper Sanding Tools

As mentioned, quality tools matter when sanding epoxy resin to achieve desired results.

More specifically, the correct tools make the process easier, produce great results, and promote safety.

Why do quality sanding tools matter so much?

In order to summarize the benefits of quality sanding tools without getting too long-winded, I list the 4 essential sanding tools below along with the value it provides.

Random Orbital Sander for Resin

First, the festool RO125 (RO90 & RO150 as well) are dual mode, variable speed sanders with a rotary (rotex) and random orbit mode.

The rotary mode on speed setting 5 works best rather than random orbit mode.

Random orbit mode vibrates, which produces pigtails and inconsistent results.

Rotex mode simply rotates in a circular motion, which works better for epoxy resin.

A soft sanding pad provides a suitable backing for the sandpaper.

Resin Sandpaper

The sandpaper is equally as important as the sander.

Most of the time, I use Festool Granat NET sandpaper when for epoxy resin.

NET abrasives capture dust from the entire sandpaper area and lasts a long time.

For this project, I ran out of Granat NET sandpaper.

In turn, I used the traditional Rubin 2 sandpaper.

Rubin 2 sandpaper works just as well as Granat NET, but has to be cleaned more often.

As mentioned, epoxy resin is a hard surface and wears down cheap sandpaper quickly.

So, buy once cry once.

Dust Collection

Festool dust extractors remove dust very well. In fact, they lead the industry when it comes to dust extraction.

Resin dust is carcinogenic and will damage your lungs. Obviously, it’s not good to inhale these particles.

A HEPA certified dust extractor collects dust at the source, before it enters the air.

The less dust in the air, the less dust exists to inhale. For the occasional airborne dust particles, use a dust mask.

Your health takes priority over everything else, so save up to purchase a quality dust extractor. “Buy Once, Cry Once” is an old saying, but always proves to be true.

4. Sandpaper Grit Sequence and Direction

When sanding epoxy resin, the sanding grit sequence and sanding direction are important.

Grit Sequence

It’s a good idea to start sanding epoxy resin with 120 grit sandpaper.

The best option is to start sanding at the higher grits if possible.

The ideal sandpaper grit sequence is as follows: 80, 120, 150, 180, 220, 320, 400, 500, 800, 1000, 1200, 1500.

Keep in mind, I rarely go higher than 400.

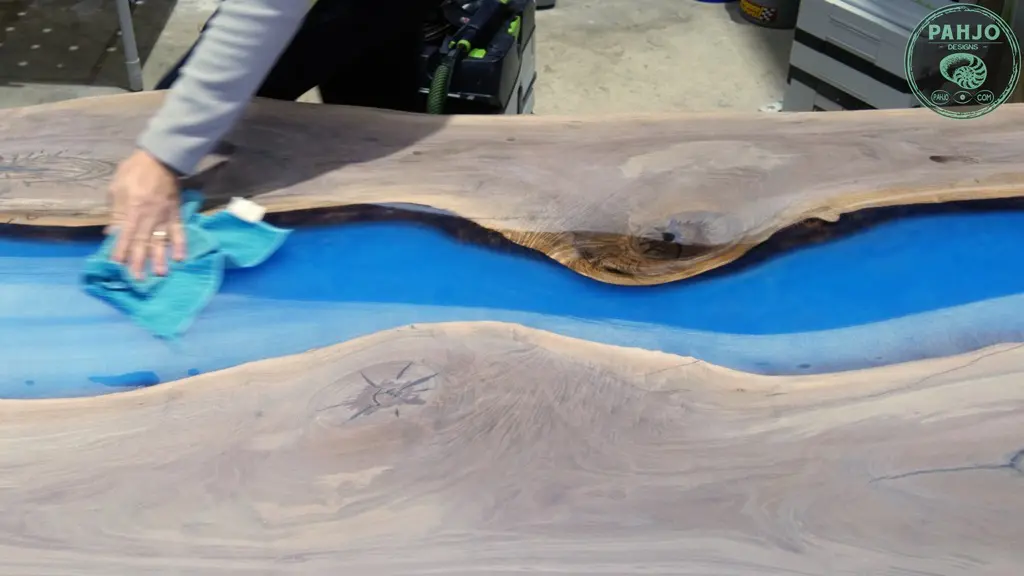

Epoxy Resin Sanding Technique

First, sand the epoxy surface vertically (shorter distance) while overlapping the previous pass by 50%.

Remember, clean the sandpaper after 1 or 2 passes.

Then, sand horizontally (longer distance). Be sure to move at a steady and consistent pace.

Finally, wipe the entire surface with a damp clean rag or microfiber cloth after each grit.

5. Control Epoxy Sheen with Sandpaper Grit

I must admin, I don’t like an epoxy glossy finish.

A flat/matte finish because it simply looks more natural.

Additionally, this tip works best with Odie’s Oil finish.

Odie’s oil is one of my best finishes for epoxy wood table tops.

The final sanding grit controls the sheen level of the epoxy resin surface.

- 220 to 320 = Flat/Matte

- 400 to 600 = Satin

- 800 to 1000 = Semi-Gloss

- 1200 and Up = High Gloss

To get the best finish for epoxy wood tables, use Rubio Monocoat or Odie’s Oil.

I received a few questions in the past on how to achieve 2 different sheen levels on the same table.

In other words, the epoxy portion of the table has a glossy surface while the wood portion has a flat finish or matte finish.

While this is possible, I always recommend against it for maintenance reasons.

On this table, my customer requested Rubio so that’s what I used.

Conclusion

I hope these 5 simple tips for sanding epoxy resin helps you sand epoxy like a pro.

Please leave a comment down below if you have additional tips to share, questions, or comments.

Related Posts:

Frequently Asked Questions

In order to sand an epoxy resin table, use an orbital sander to sand the surface vertically and horizontally. Then, use the following sandpaper grit sequence: 120 grit, 150 grit, 180 grit, 220 grit, 320 grit, 500 grit, 1000 grit, and 1500 grit.

To sand epoxy resin, use an orbital sander with proper dust extraction.

To make resin shiny after sanding, apply polish with a polishing pad. Then, buff the polish off with a microfiber towel or buffing pad.

Yes, the dust produced from sanding epoxy resin is dangerous. Use a dust extractor and a respirator when sanding epoxy resin.

MARK TERREAU

Thursday 18th of March 2021

Thanks for all the good information. If I wanted to try polishing, what type of polish and what type of pad would I use?

Pahjo Designs

Sunday 21st of March 2021

Hi Mark,

I prefer festool polish and pads.

Checkout this post for more finishing advice: https://do-daddy.com/best-finishes-epoxy-table-top/

Chandler

Wednesday 17th of March 2021

Thank you very much for all the tips. Especially on what grit to sand to for the sheen you want. These are hard bits of information to find.

Pahjo Designs

Thursday 18th of March 2021

You are very welcome.

trog

Sunday 7th of February 2021

You da man! Clear and concise! In a wicked short time, I've learned what has caused my myriad mistakes and frustrations and how to correct them.

Pamela Chant

Friday 5th of February 2021

As a beginner, I needed this! Thanks!

BROOKE SOMMERDORF

Wednesday 6th of January 2021

This was extremely helpful, thank you!

Pahjo Designs

Friday 8th of January 2021

You are very welcome!